Hand on heart, did you know what's behind the German phrase "driving into the blue"?

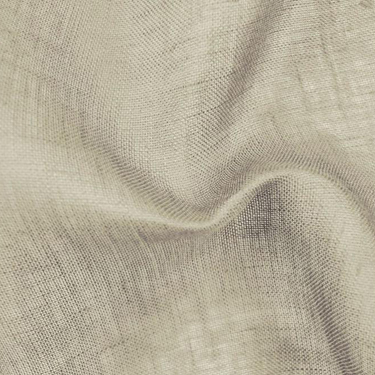

Originally, it alluded to a visit to a flowering flax field. For thousands of years, the blue flax provided an invaluable raw material: flax fibers. They are also the basis of our unique LinColor® material. Our name alludes to this, because "lino" or "lin" stands for flax and linen in Romance languages.

The importance of flax in human history is exciting and amazing, if a little forgotten: Who knows that our ancestors were making linen clothing some 30,000 years ago? Linen was considered one of the most precious fabrics. Woven moonlight is what the Egyptians called it more than five thousand years ago because of its peculiar beauty - and they wrapped the mummies of their pharaohs in linen cloth. In ancient Greece, linen was used to make body armor for military purposes and offered as consecration gifts in temples. Many of the most important works of art in painting have been created on canvas since the Middle Ages and would have faded long ago if the artists had not protected them with linseed oil varnish. Did you know that linseed oil is also the basis for the production of linoleum? And that in the Middle Ages the oil of the linseed plant was used to polish knights' armor to a high gloss?

Even if we are no longer aware of it, linen found its way into all areas of daily life:

From diapers to burial garments, it accompanied people at close quarters. The linseed and the linseed oil pressed from it was a sought-after food and tonic, and the woody parts from the inside of the plant were burned.

From ancient times to the Middle Ages, all clothing in Europe was made primarily of linen and wool.

And the worn out clothes (not to say the rags) with the beginning of the modern times were torn into the smallest pieces to so-called rags, plucked, pounded until a uniform fiber pulp was formed. In the famous paper mills of Europe, the most precious handmade papers were made from this fiber pulp. For us today, a clear case of upcycling!

In the field of textile manufacturing, things changed with the triumph of cotton.

And paper manufacturing was turned upside down with the invention of the so-called Dutchman, a machine that finely grinds vegetable fibers to prepare them for the production of paper. (In our factory, we also use such a small-scale Hollander to finely grind the flax fibers for the LinColor® material). In the meantime, clothing made of linen has regained its place in the textile industry against the background of sustainability and ecological awareness. After all, linen is a natural product and is considered the most environmentally friendly and durable of all textile fibers.

Thanks to new technologies, flax is now used in a much wider range of applications

in so-called biological fiber composites, which can be used to make just about anything from violin cases and biodegradable luxury urns to hip designer chairs.

That brings us back to jewelry.

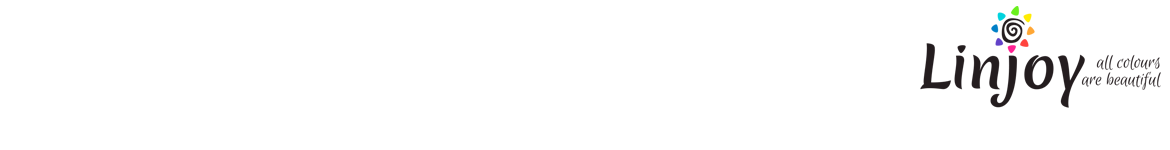

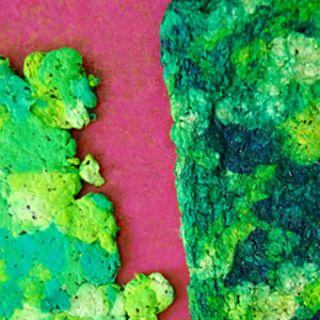

And the LinColor® material from which we lovingly and painstakingly form beads and inlays by hand in our manufactory. LinColor® is the name of our completely new material made of flax fibers, the basis of our unique jewelry collection. In a multi-layered handicraft process, we use it to produce high-quality "jewelry stones" made of plants, in brilliant colors and marbling.

The LinColor® material with its warm, velvety surface is indescribably fascinating.

It is amazingly light, lightfast, waterproof and permanently beautiful! We have taken a close look at it: before a finished piece of jewelry leaves our house, the LinColor® material has passed through our hands in no less than 20 different work steps. From the grinding of the flax fibers, to the dyeing and drying, the production of plastic masses, the shaping and finishing, the punching and grinding, and right at the end, the gluing in of the finished inlays or the drilling and threading of our various hand-shaped beads.